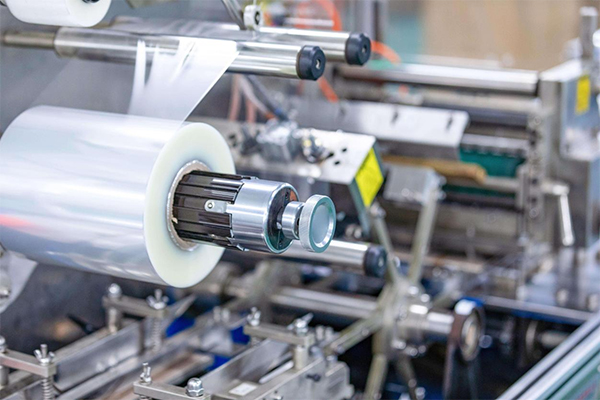

Packaging Industry

The packaging process includes main processes such as filling, wrapping, and sealing, as well as related pre- and post-processing processes, such as cleaning, feeding, stacking, and disassembly. In addition, packaging also includes processes such as metering or printing the date on the package. The use of packaging machinery to package products can increase productivity, reduce labor intensity, meet the needs of large-scale production, and meet the requirements of cleanliness and sanitation.

Sensor

Versatile, rugged laser distance sensors offering superior performance and capable of detecting sub-millimeter changes in distance.

- Discrete, analog (0 to 10 V or 4 to 20 mA), clear object, and IO-Link models available

- Q4X600 high resolution models are now available with analog output and even higher excess gain to solve more applications

Stepper Motor

A stepper motor is a type of brushless, synchronous electric motor that divides a full rotation into a large number of equal steps. Unlike conventional motors, stepper motors move in precise, discrete increments, making them ideal for applications where accurate positioning, repeatability, and speed control are crucial.

Servo Motor

Rtelligent RSN series AC servo motors, based on Smd optimized magnetic circuit design, use high magnetic density stator and rotor materials, and have high energy efficiency.

- Multiple types of encoders are available, including optical, magnetic, and multi-turn absolute encoder.

- RSN60/80 motor have more compact size, saving installation cost .

- Permanent magnet brake is optional, moves flexible, suit for Z -axis applications

Planetary Gearbox

Gearboxes for stepper motors are mechanical components that reduce the speed and increase the torque of stepper motors. They are especially useful in applications requiring high precision, controlled motion, and improved load-carrying capabilities. Using the right gearbox with your stepper motor helps enhance performance, reduce wear, and increase efficiency.

Automation Product

A VFD, or Variable Frequency Drive, is an electronic device that controls the speed and performance of an AC motor by adjusting the frequency and voltage of the power supplied to it. It allows for smooth and precise motor speed control, leading to improved efficiency, reduced energy consumption, and extended equipment lifespan

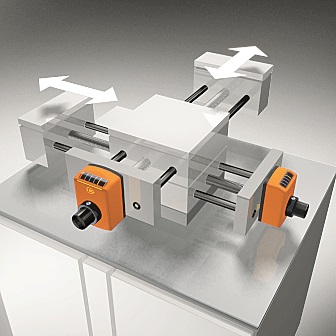

Machine Hardware Item

Our mechanical position indicators work by indicating and monitoring the movement of a machine component along a linear shaft or threaded lead spindle. They can be used in all production environments across most branches of industry. Our position indicators are perfect at ensuring that guiding elements and tools are positioned or aligned precisely and reliably in your workspace. These position indicators are mounted directly on control shafts and connected to the machine via a rear pin. They are available in three different sizes to adapt to the dimensional needs of your machinery.